News

18.5kw 10hp 8bar 10bar 13bar permanent magnet frequency screw air compressor

18.5kw 10hp 8bar 10bar 13bar permanent magnet frequency screw air compressor

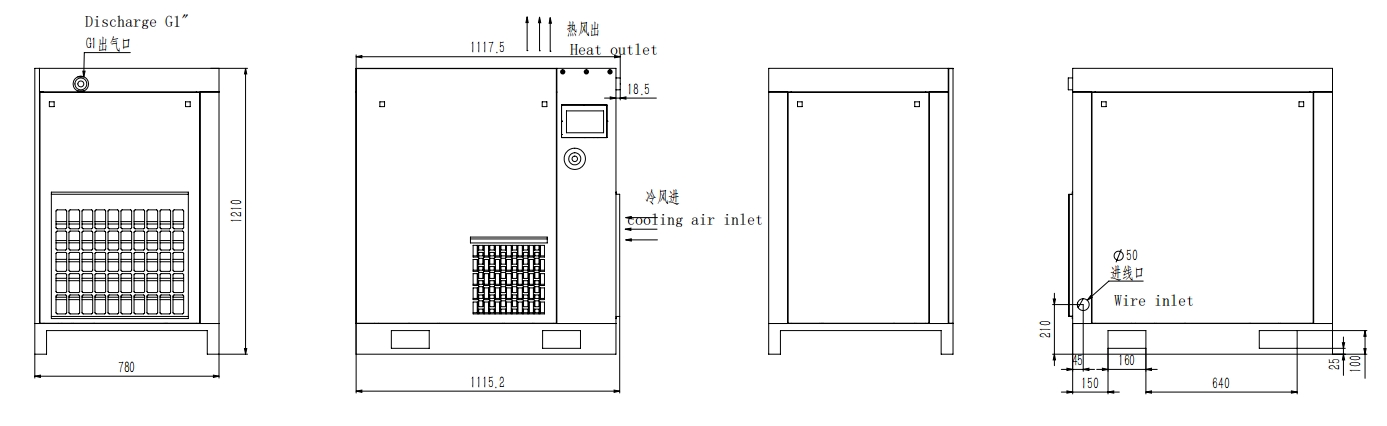

No | Description | unit | value |

1 | Model No. | 18.5kw | |

2 | Type | Stationary screw air compressor | |

3 | Dimension | 1140×780×1210mm | |

4 | Installation | Stationary without base | |

5 | Air flow capacity | m3/min | 3.0/2.7/2.4 |

6 | Discharge pressure | MPa | 0.8/1.0/1.3 |

7 | Discharge oil content | ppm | ≤2 |

8 | Discharge temperature | ℃ | ≤ambient temp+10~15 |

9 | Way of transmission | one shaft | |

10 | Lubricant volume | L | 18 |

11 | Way of cooling | Air | |

12 | Cooling air volume | m3/h | 4725 |

13 | Ambient pressure | 760mmHg | |

14 | Ambient temperature | ℃ | 0 ~ 45 |

15 | Noise level | dB(A) | ≤68 |

16 | Weight | Kg | 370 |

17 | Discharge connection | / | G1” |

Product Description

22kw permanent magnet vsd screw air compressor

22kw/30hp

permanent magnet motor

with inverter variable speed

big frequency range

saving 30%-50% power

direct driven

380v/50hz 3phase

work pressure: 8bar 10bar

controller: MAM6070 PLC with touch screen display

usd1550/set EXW factory

3.8m3/min refrigerated air dryer

220v/50hz single phase

refrigerant R134A

work pressure 6bar-16bar

usd490/set

300 liters air tank

our 11kw fixed speed screw air compressors in testing.

our 7.5kw permanent magnet VSD screw air compressors, in making package.

our 7.5kw fixed speed screw air compressor in making package

our 22kw 30hp screw air compressor fixed speed 380v/60hz in making pacakge

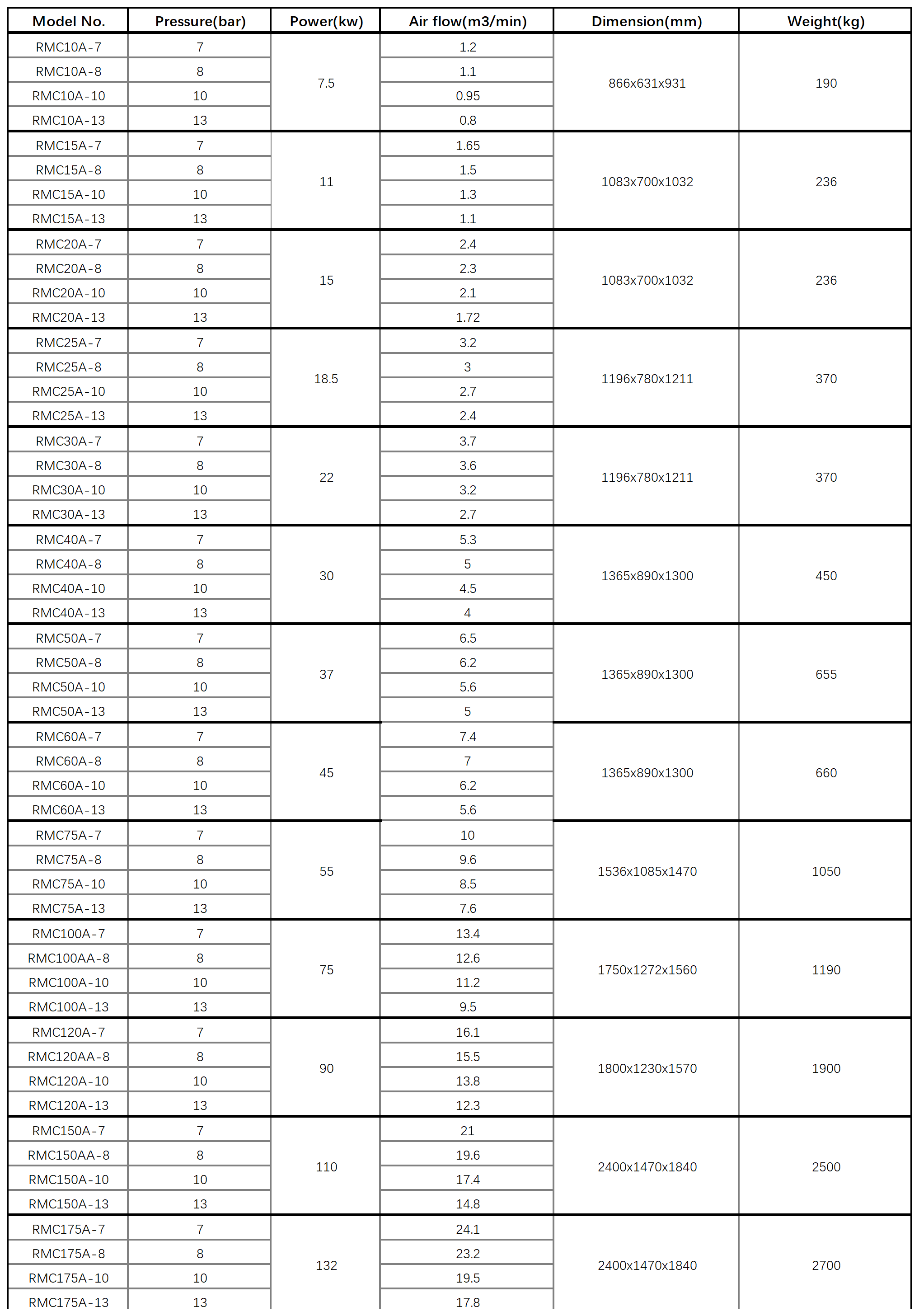

General parameters of our permanent magnet vsd screw air compressors

Features of permanent magent vsd screw air compressor:

Controller: MAM6070 / MAM6080 PLC with touch screen display

Intelligent controller, simple operation, complete functions, real-time monitoring of operating conditions, convenient maintenance.

Screw Air-end / Screw air compressor block / Compressor rotors: BAOSI / HANBELL

Adopts large screw rotor, multiple shaft seals, few wearing parts, compact structure, large displacement and high stability

Permanent Magnet Electric Motor: IP23 / IP55

Variable speed range 70hz to 240h,Speed range is from 25% to 100%,Significant energy savings,Synchronous operation,Higher torque-to-size ratio

High-frequency Inverter:

High effectively reduces the magnetic field interference generated by the inverter and saves electricity.

Oil Separate Tank:

The use of excellent oil and gas separators and precise oil and gas separation filter elements can reduce the oil content of the exhaust gas in the compressor and reduce the power consumption of the unit.

Oil Filter:

The oil filter adopts a filter paper rotary filter to filter out impurities in the lubricating oil, clean and lubricate, and increase the service life of the compressor

Cooling system:

The high-pressure cooling system is adopted, and the heat dissipation efficiency is high, so that the air compressor can still work continuously in a high temperature and high humidity environment

Intake Valve ASSY:

The intake valve assembly automatically adjusts the amount of intake air to achieve a more energy-saving intake state. At the same time, it has a relief function to discharge the internal air pressure

Our Services

Long interval maintenance periods:

Nearly ideal isothermal compression, direct driven method, smart configuration and precision component design and machining, long bearing service life, all of the above essentially extends interval between regular periodical maintenance.

Company Information

Shanghai Royal Machinery Co.,Ltd is a high-tech enterprise which specialized in sales and service of compressed air system equipment, and after-treatment equipment, booster compressor, diesel generator and drying equipment, etc.

We have an experienced team. It not only provide high-quality and high-efficiency compressors for users but also provide the best solution for air system equipment during before-sale, selling and after-sale.

Welcome to contact us for inquires and quotation.

Packaging & Shipping

All of our screw air compressors are packed by export standard plywood case:

Because of screw air compressor package volume and weight, most of our screw air compressors are shipped by sea.

Related oil injection screw air compressors and oil free air compressors

PM VSD variable speed screw air compressor

15kw oil free screw air compressor pure water injection:

3.7kw-22kw oil free scroll air compressors, class "0" compressed air

All in one screw air compressor, tank mounted with air dryer and line filters, 7bar-16bar for laser cutting machine

Screw air compressors RFQ questions:

1. we suggest replace oil filter at the first 500 hours working time for a new screw air compressor, meanwhile to replace lubrication oil and oil separator filter together, lubrication oil we advice shell brand 46# semi-syntheitic (Shell corena S3 R46).

2. after that, replace oil filter every 1500-2000hours which according to screw air compressors working conditions, if there is dusty, we advice to replace every 1500 hours, air filter element and oil separator filter are same, to replace them every 1500hours to 2000hours, if expiry time, our screw air compressors PLC will alarm and show error code on PLC display.

if not replace filters over that time, and clear alarm to continue working, may cause oil lakage, which you can see oil come out from safety valve and oil seprator tank cover....

3. there are also other small problems which screw air compressors meet frequently, such ask lack of phase,fuse burnt, lubrication oil less caused overheat, cooler blocked.....welcome to contact with us please, we have rich experience of selling and after-sales maintenance of all screw air compressors, will give best soupport.

Categories

Contact Us

- +86-15800773412

- +86-21-59989099

- +86-17301863604

- [email protected]

- susansusan258

- +86-15800773412

售前客服

售前客服