News

The harmness if do not maintain a screw air compressor

The harmness if do not maintain a screw air compressor

The harmness if do not maintain a screw air compressor

Let's talk about the 5 major hazards of unmaintained screw air compressors.

1. The oil return pipe joint of the screw air compressor is not cleaned: if it is blocked, a small part of the oil will enter the pipeline with the air after separation, resulting in large oil loss and oil shortage.

2. Grease the main motor bearing of the screw air compressor from time to time: the bearing is worn out until the main motor burns out.

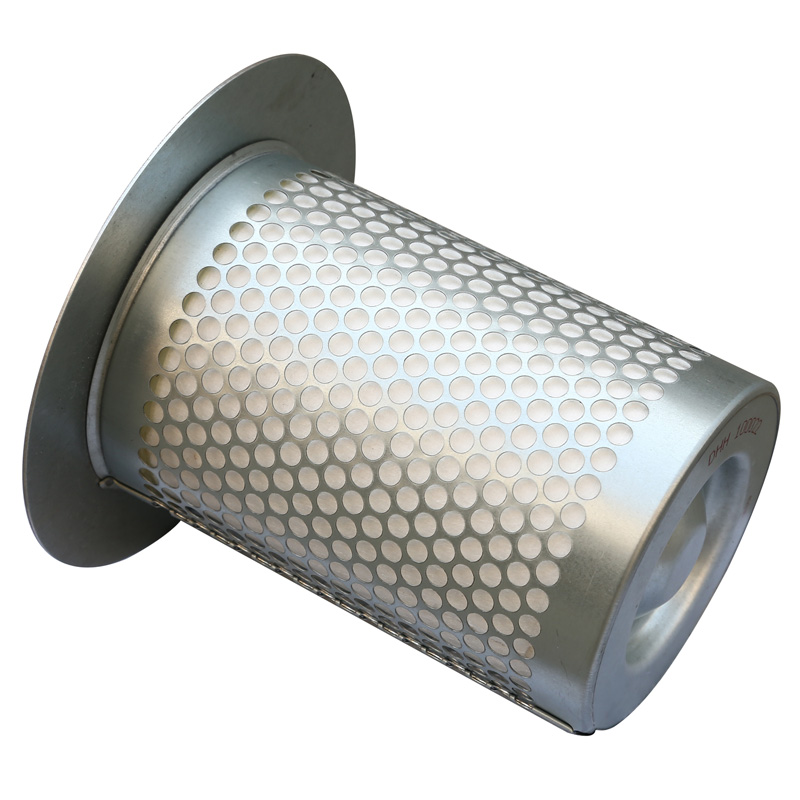

3. Unscheduled blowing and unscheduled replacement of the air filter element of the screw air compressor will cause: the air filter element is blocked, the air intake volume is reduced, and the exhaust volume is also reduced. Unscheduled replacement will cause negative pressure to increase and press through, pollutants enter the machine, block the oil filter, oil separation core, deterioration of cooling lubricating oil.

4. The screw air compressor oil filter is replaced irregularly: as the pressure difference between the front and rear increases, the excess oil decreases, and the exhaust temperature of the screw air compressor rises and stops. If the front and rear pressure difference is too large, the pollutant enters the machine. Inside, the oil separation core is blocked, and the host is worn out.

5. The oil separator of the screw air compressor is not replaced: as the pressure difference between the front and rear increases, the current of the main motor increases, and the exhaust volume decreases. If the front and rear pressure difference is too large and breakdown, the cooling lubricating oil will enter the pipeline with the air until it runs out, and the main engine will stop when the exhaust temperature rises.

The above are the maintenance steps and precautions of the screw air compressor. The daily maintenance and inspection records of the screw air compressor can be recorded regularly or irregularly, or recorded after the maintenance. Accurate records are conducive to the appearance of the air compressor.

The main contents of the maintenance record include inspection, cleaning, adjustment, supplementation, replacement and corresponding time. The maintenance period of the screw air compressor is provided by the manufacturers with reference time. If the air compressor is installed in a clean and low temperature environment, the service period can be appropriately extended. The correct service period should be formulated according to the using environment of the air compressor .

Categories

Contact Us

- +86-15800773412

- +86-21-59989099

- +86-17301863604

- [email protected]

- susansusan258

- +86-15800773412

售前客服

售前客服